|

| November 30, 2021 | Volume 17 Issue 44 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

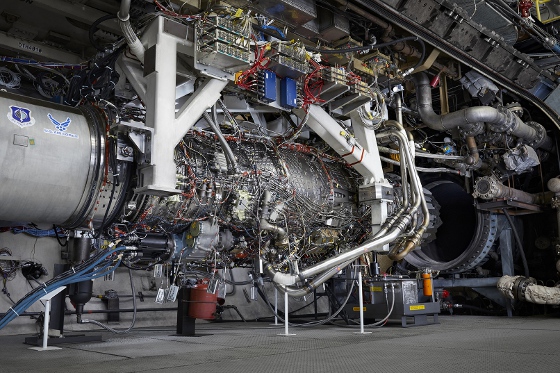

GE concludes testing of new F-35 Lightning fighter jet adaptive cycle engine prototype

GE has completed ground-based testing of its first XA100 adaptive cycle engine for the Lockheed Martin F-35 Lightning fighter jet that will be used by the U.S. Air Force. The new engine combines three key innovations to deliver a generational change in combat propulsion performance.

The three key innovations of the engine combine to deliver new performance capabilities and efficiencies:

- An adaptive engine cycle that provides both a high-thrust mode for maximum power and a high-efficiency mode for optimum fuel savings and loiter time;

- A third-stream architecture that provides a step-change in thermal management capability, enabling future mission systems for increased combat effectiveness; and

- Extensive use of advanced component technologies, including ceramic matrix composites (CMC), polymer matrix composites (PMC), and additive manufacturing.

By the numbers, GE says the new 45,000-lbf-thrust-class engine will provide a 50% improvement in loiter time, a 35% increase in range, a 25% reduction in fuel consumption, a 10% increase in thrust, and 60% heat absorption to accommodate next-generation weapons technology (which may include directed energy or laser weapons) -- all within the same physical envelope as current propulsion systems.

GE initiated testing at its Evendale, OH, altitude test facility on December 22, 2020. The engine's performance and mechanical behavior were consistent with pre-test predictions and fully aligned with the U.S. Air Force's Adaptive Engine Transition Program (AETP) objectives. This successful test validates the ability of GE's XA100 engine to deliver what the company is calling "transformational propulsion capability" to fighter aircraft.

The XA100 was developed under the U.S. Department of Defense's Adaptive Versatile Engine Technology (ADVENT) and Adaptive Engine Technology Development (AETD) programs. It is the only engine that combines outstanding fuel burn with increased, fighter-level thrust, which should enable next-gen military combat aircraft to go greater distances and engage more targets.

VIDEO: XA100 engine overview.

What makes this engine so special? According to GE, "Unlike traditional engines with fixed airflow, the XA100 is a variable cycle engine that will automatically alternate between a high-thrust mode for maximum power and a high-efficiency mode for optimum fuel savings -- and that means a whole new book of operational possibilities for the U.S. Air Force."

It employs an adaptive fan to direct air into a third bypass stream, enabling greater fuel efficiency or to act as a heat sink for cooling. Air from this third stream can also be directed to the core and fan streams when additional thrust is needed.

The XA100 adaptive cycle engine automatically alternates between its high-thrust and high-efficiency modes. High-thrust mode directs the majority of air through the engine's core and fan streams, delivering greater thrust during combat engagements and helping pilots execute their missions effectively. High-efficiency mode directs air through the engine's third stream to dramatically reduce fuel consumption, provide greater range, and allow pilots to persist longer in areas of interest with reduced risk.

VIDEO: Rotating ceramic matrix composite (CMC) parts in the XA100 engine.

"This was the most heavily instrumented engine test in both GE and U.S. Air Force history," said David Tweedie, GE Edison Works' General Manager for Advanced Combat Engines. "We were able to obtain an immense amount of high-quality test data proving out the engine's capabilities and demonstrating a good return on the Air Force's investment.

"The Air Force has been an integral part of the team throughout the entire design and test process. That extensive involvement has been key in reaching this milestone. It has been an incredible partnership and collaboration."

"We were exceptionally pleased with how the engine performed throughout the test," added Tweedie.

Full-scale prototype engine testing in the AETP program is the capstone of a multi-year technology maturation and risk-reduction effort to bring adaptive cycle engines to full maturity in close partnership with the U.S. Air Force. Efforts began in 2007 with the Adaptive Versatile Engine Technology (ADVENT) program, continued in 2012 with the Adaptive Engine Technology Development (AETD) program, and culminated in the launch of AETP in 2016. This development work provided GE a solid foundation of design analysis and empirical test activities to achieve a full-scale prototype engine successfully. GE is the only engine company to compete for, be awarded, and complete both the preceding ADVENT and AETD programs.

Assembly of GE's second prototype XA100 engine is well underway, with testing on that engine expected to begin before the end of this year. Once complete, that will conclude the major deliverables of the AETP program.

Sources: GE, USAF, Wikipedia

Published November 2021

Rate this article

View our terms of use and privacy policy